Hi Kum,

did you get my post? with the request for the tech details?

Ive have my philospher’s stone to hand and my medieval alchemy books ,(problem is there in Latin!) where I know is the magical answer to your needs, cant refer to it without your tech imput.

Still awaiting your reply.

Ted.

Greetings,

Sorry about mixing topics. I will open another thread to ask about powdered solder.

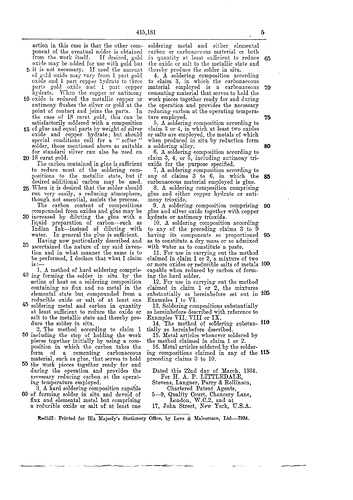

I see all of H.A.P. Littledales patent did not load and I will try to load it in its entirety here.

Dear Vladimir,

Thanks for the response.

Pls. find the answers on your tech queries:

- furnace oxidising atmosphere or reducing? - The furnace is a

continuous belt soldering furnace with free from oxidising atmosphere

(using H2,N2 gases) - size of wire used in chain? in mm - *Size varies from 0.25mm to 0.5mm

and we have 3 basic chains *(Cable/Anchor, Curb & Box/Venetian) - how many links per cm. - (links/cm vary from big chain to small chain)

*-For cable, min- 65 ~95 links/cm *

-For curb, min- 23 ~74 links/cm

-For Box, min - 64 ~137 links/cm

4.how many meters of chain per hour? - The soldering speed (belt speed)

varies from 2 ~3 mtr/min

5.carat of gold? - Majority in 22kt, and some in18kt and now we have

started trying 14kt also. (The percentage ratio approx. - 80:15:5)

Pls.suggest the suitable process by using zinc & talc powders.

Or any other alternates instead of powder method to avoid chain link cut

and fusion issues.

Best regards,

KUMARAVEL.R

Hi Kum,

Thank you for your reply with the required tech details.

Here in the UK, all machine made chain below 1.5mm in wire diameter is fused in a reducing atmosphere tunnel furnace as follows.

The wire is always a double’ material, that is 20% of the wire diameter is 22ct solder in the middle of the wire.

The chain making machine butts the 2 cut ends of each link

touching together, then, when heated in the furnace this melts and fills the joint properly.

there are no cuts? ot links fused together.

No other method is used. no zinc nor other powder.

You will need to get your wire maker, to make it to this specification and then you will get perfect results.

On chain as fine as you specify, my experience of the machine made chain its always done this way.

Please advise how you progress with your wire supplier.

If you draw it yourself, you start with an ingot with a hollow center into which you introduce the 22ct gold solder.

then proceed to 1st roll down theingot, then draw the rest of the way to your required dia.

Ted.