Hi there, I am trying to find out about H.A.P Littledale - a London

goldsmith, early 20th century. I’ve heard he wrote a book (about

granulation) but I cannot find out the title. Does anyone know of

him or the book he wrote? Thank you Eileen Procter

Hi Eileen, Out of curiosity due to your question, I found this info:

http://www.jewelry-time.com/Archive/ANTIQUE/granulation.htm

A cut and paste from the above site:

“H.A.P. Littledale in London, Hans Michael Wilm in Munich and

Elizabeth Treskow in Essen synchronistically arrived at the same

practical method of achieving this type of granulation, based on a

theory proposed by Dr. Hans Joachim Wagner in 1913. Littledale is

generally credited with the reinvention because he patented his

technique in 1933 and later presented his findings in a lecture

titled “A New Process of Hard Soldering and its Possible Connections

with the Methods used by the Ancient Greeks and Etruscans” at

Goldsmith’s Hall in 1936. Littledale was acquainted with Wilm and

Treskow, as their work was on display in Goldsmith’s Hall, and they

were acknowledged guests in the audience at the time Littledale

presented his paper. Unfortunately, there is little in print about

the work done by Littledale and Wilm.”

So, it looks like it may have been a paper rather than book?

Marta

Dear Eileen, I don’t know of a book by Littledale, but he patented

his technique (granulation based on copper salts) in 1933, and then

presented his findings in a lecture titled “A New Process of Hard

Soldering and its Possible Connections with the Methods Used by the

Ancient Greeks and Etruscans” in 1936. Apparently there is very

little in print from Littledale, but two people in the audience at

the time of the presentation – Hans Michael Wilm and Elizabeth

Treskow, are both fairly well published, so it is possible that

their works contain references to Littledale’s work. I’ve done

quite a bit of reading from Treskow, but since I wasn’t looking for

specific references to Littledale, I couldn’t tell you off-hand if

they were there. However, academics will point out that though

Littledale got the patent, Wilm and Treskow arrived at very similar

methods at the same time, so there is definitely value in reading

their work if it is practical application you are looking for. Hope

this was helpful!

Claire

H.A.P Littledale lectured - but I don’t think he published. Contact

Goldsmith’s Hall in London and they may details.

Tony Konrath

http://www.goldandstone.com

H.A.P Littledale lectured - but I don't think he published. Contact Goldsmith's Hall in London and they may details.

Not sure if he published in book form, but he did file a patent

application for his “eutectic soldering” method, ie granulation

method. The patent paperwork has a lot of the details of what he

worked out. Somewhere, in a box in the basement, I suspect, I had a

zerox copy of that paperwork, obtained during a long ago jewelery

class. If I got a copy, there must be others around too. And I have

a vague memory that at least some of the texts of his lectures were

transcribed and published, as that, too, I recall seeing as a

chapter in someone elses publication. Again, when I saw it, it was a

dim zerox of the original, so I can’t tell you from whence it was

taken.

Not much help, other than to suggest that a continued search would

be potentially fruitful…

Peter

My xerox of the Littledale Lecture is headed “Lecture IV, Febvruary

24th, 1936” and is on pages 44-63—but I don’t have the name of the

journal in which it appeared, and can’t locate my original source

notes on this one. But I got it at the library in Goldsmiths’ Hall

in London, and I’m sure the librarian there will be familiar with

this lecture.

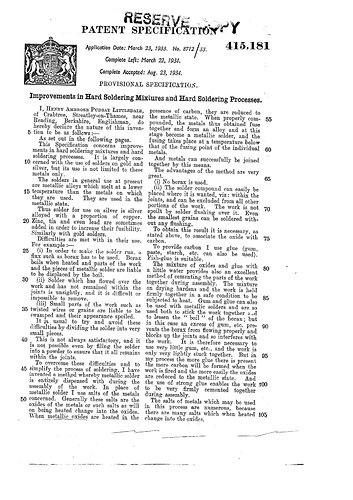

The patent is No. 415,181, March 23rd 1933, and can be ordered from

the British Patent Office. I did it over 25 years ago, so I don’t

remember the details regarding ordering, etc. Should be easy in

today’s internet world…

Janet in Jerusalem

Greetings,

I realize this is an old topic but I was able to find H.A.P. Littledale’s patent,

Going to try making a powdered solder described in a chapter 7 of Castellani, written by Jack Ogden.

Anyone out there have success making powdered solder? How did you do it? What was the formula?

Kindest regards,

Lois Gore

Lois-

I used to work with and learned to make fine chains from a south east

asian war refugee Seng Au. He used to make his own paste solder for making

chains.

Because he made them out of high karat gold, usually 22kt he’d file up 1/2

22kt gold and 1/2 18kt hard yellow solder. He’d then mix the two and

further grind them to a finer powder by placing the filings between two

very clean flat files and rub them together. Then he’d run a strong magnate

through the dust to remove any traces of the ferrous file metals and add

thinned paste flux and mix. He had a very tiny scoop that he made to apply

the paste solder to the links.

No fancy recipes. Just metal and flux.

Hope this helps.

Have fun and make lots of jewelry.

-Jo Haemer

www.timothywgteen.com

Hi Lois,

Interesting tho this patent is, the crunch line is the last sentence.

To be used in a reducing atmosphere.

Now how many of the metal workers here on this forum and generally elsewhere have whats needed to do this kind brazing in a reducing atmosphere?

My guess is no one.

To use such a paste with this atmosphere one needs an industrial set up using a tunnel kiln and cracked ammonia.

I use paste solders for specific purposes and I go to a supplier that makes it all day. with a guaranteed formula and temp range of use.

Glad youve the time to experiment !.

My advice is work out what advantages you will get from using this way of brazing metals and go to a specilist maker.

time is too valuable unless its just a hobby, where your not needing to make a living from your efforts.

~Ted,

who has used this reducing process in an industrial setting.

Actually… The way that this material is used means that the carbon included in the paste acts as a reducing agent and provides the required atmosphere, very much like that used in granulation.

To vladimirfrater,

Well I for one have a simple reducing atmosphere setup which was probably quite common in Littledale’s time: an old torch that runs on benzine (petroleum naptha) and a foot bellows. If you bend the tubing which attaches the bellows to the torch with the free hand while you are soldering, it restricts the air passage and you get a highly reducing flame…:-)… I got the setup about 40 years ago from a dental supply in China, and it was my only torch for many years. Even without bending the tubing, it’s still more of a reducing flame than an oxidizing flame. And of course working on a charcoal block also increases reduction.

Greetings,

Very interesting. Thank you Janet. Love the tip about using files and a magnet.

Ted, would you like to share your supplier for paste solder. Would love to experiment.

Tony, I am interested in using the paste or powdered solder for granulation. Would the heating atmosphere created with a bushy flame (acetylene) and a mini kiln create a reducing atmosphere? Or should I use a charcoal block?

Thank all for reviving this topic.

Kind regards,

Lois

Ishiatsu,

Granulation is done by fusing, no solder.

You can see it done on YouTube.

Hi Janet,

On this forum, there are a few folk whos opinion I respect, your one of them, why? because your approach is from a studied technical position. Rather rare even in these days.

So yes I too use a reducing atmosphere for pre heating bronze prior to minting. i have a propane flame from a 2in dia burner feeding into a s/steel 60 mesh enclosure with a lift up lid. The mesh lasts around 2500 cycles then its burned out and has to be remade. This is for the average hot minting production run.

Inside this enclosure is an atmosphere that can be 100% oxygen free or with the air control on the burner adjusted to run very rich fully reducing. The interior of the enclosure can be as high as 800deg C. because the mesh will glow the right colour red. also one can see the metal being heated come up to the same colour so I know its temp. Likewise the metal surface is bright to indicate a reducing atmosphere. Davy miners lamp principle.

Be that all as it may , the patent specifically quotes in its last line its operating parameters.

As we dont know who or when this particular paste is being used one can only go by the words.

Also in the aero space, nuclear, microwave magnetron and vacumn industrial world hand held or basic techniques will not do.

That is why cracked ammonia tunnel kilns were developed.

These are also adapted and used in the watch case assembly industry to join the braided gold wrist bands to the watch movement cases.

I may have mentioned it before but ill do so again, I was blessed with an aviation engineering practical hands on degree some 60 yrs ago and it defines all do today.

thats why Im able to develop and apply industrial techniques to all I make.

Tho there still problems of course, like im struggling with minting some small leaves in 18ct gold to apply to a s/steel cuff bracelet I am making like I made for myself some 41 yrs ago. Ill get my IT guru to post up a picture. Its as good as the day I made it.

The 1st production batch of 40 off of one of 10 bracelet designs im making for my major retrospective exhibition for next year in June, are now completed. a lot of work to do in the next 10 months. It will be my 50th year.

If your in the UK then youd be welcome to come to it.

Ted.

.

Hi Lois,

sure,

go on line to Cookson gold, in the UK, ( where im based)

They supply paste solders in syringes in a whole range of silver and crt golds . there all Swiss made. Youll need a deep pocket tho!. Quite unsuitable for granulation in my opinion.

Look at other ways to make granules. its not difficult.

They are /were Johnson Matthey one of the oldest metal suppliers in the UK, thoroughly reliable and professional , not only to our game but to the wider industrial world. I have all their catalogs and tech data going back to the mid 1960’s.

Ive had some exotic products made for me by them in the past. Like fine gold fine silver double’ material 1/1000in fine gold and 9/1000in fine silver sheet. for a specific enamelling project.

there good.

Ted.

Hi…Edward Vladimir Frater,

I m in India and handling a small chain mfg plant.

We are frequently facing link cut during soldering through continuous belt

furnace.

Recently i came to know that, there is a special liquid and powder for

soldering of machine made chains without any solder cut.

Anything you know within your network, pls. share and would be very helpful

to us.

Thanks in advance.

Best regards,

KUMARAVEL.R

- “The Best Motivation is Self-Motivation”*

Hi Kum,

Can you specify

- furnace oxidising atmosphere or reducing?

- size of wire used in chain? in mm

3 how many links per cmm.

4.how many meters of chain per hour?

carat of gold?

see my reply to Lois for paste solders.

as a start.

Ted.

What Richard said about granulation. It’s all fused.

-Jo Haemer

Victoria Lansford has a very nice introduction class about granulation through Craftsy. (Craftsy.com, under Jewelry)

It is basic (what I needed) but seems thorough to me.

If you like to watch granulation being done (but no instruction or explanation), look up Filigreenus on Youtube. Some amazing work.

Tricia