Hi - I like making filigree rings which consist of lots of small sections of wire shaped into horseshoes, loops, curls, etc which I have to solder together. Because they’re so small the pieces tend to move/separate when you start to heat them and the flux bubbles (both Auflux and borax do that). I’m going to try embedding the pieces in the surface of potters clay to see if that holds them still long enough to solder them together. Has anyone got any tips for doing this or suggestions for other ways of securing small pieces, to keep them in contact with each other? Plaster of Paris/dental investment might work but I’d have to wait until it set and dried out before soldering, which would really drag the process out.

Hi Davidcan

Back when I was a student I think I used plasticine.

I don’t recall any problems.

hi

here is a great article by Victoria Lansford on russian filigree, done for Ganoksin, thst may interest you.

She also has a russian filigree video for sale

i have the streaming version and it is very informative

there is also a DVD version

julie

If you don’t want to solder in plaster you can pin them in place on a charcoal block with short lengths of binding wire.

Back in the day when I was learning my teacher used ( wax based ) play Doug, to place the parts just as you would see them from the front , and then would put a can ( bottom cutted out) around the whole thing , and then casted dental investment in the can , once it settled he would flip it pull out the playdough and solder from the reverse of the piece

Here is a video of the technique you are talking about. TÉCNICA con YESO para SOLDAR, 💎Clases de Joyería - YouTube

I don’t see wet pottery clay working too well for this. It would likely come apart with steam explosions when the flame came near it. Plasticine would make an even worse mess, since it would melt and burn. But either would work to temporarily hold the pieces together while you cast investment on the other side. I’d want to at least dry the investment out in an oven before trying to solder against it, but maybe you’d get away without that. Pinning the parts to a piece of soft firebrick or (as Elliot suggests) a piece of lump charcoal would be quicker, if that’s important to you.

hi Vera, thank you for sharing this video!

i always wondered if the plasticine dirtied the metal and how one would clean it, but apparently it is not a concern…i will experiment soon!

julie

In support of Victoria, I’ve did one of her filigree workshops almost 20 years ago now. You learn so much more when it is in person. You can also have a person there that knows why you screwed up and how to fix it. Well worth the time, effort, and money to take an in person class when we are once again allowed to do so.

As to holding your little wires in place, make sure they fit in tight. If it is just laid in place it is more apt to move. We were taught in that workshop to do a few wires at a time before you try to fill in a space. I found from the many years I’ve done filigree, that the best way to solder in those wire when the flux and sometimes even the solder will bubble the wire upward is to use your non dominate hand to wield the torch, and then in your dominate hand have your solder pick ready. You can gently push the wires back into place. It takes a little experimenting with it to get the control down. Practice and practice more.

There is a video on Youtube that does show how to imbed the filigree into a substance to solder it. I can’t remember what it was that was used. It was done not for jewelry, but art objects that are large and curved.

Have fun, and learn to swear in another language when the little blank blank wires take wing.

Aggie

Hi Aggie and everyone else who gave me their suggestions and comments. I’ll experiment with them all.

I’ve been learning Russian style filigree from a wonderful series of short videos by a Bolivian goldsmith called Boris Rueda, known as ‘Artifice Joyas’ on YouTube. With amazing close-up video photography he not only shows you how he makes Russian style filigree rings, pendants etc but also shows you how he makes the tools he uses!!! He provides a complete course of videos, starting with https://www.youtube.com/watch?v=URdaIIIWyS0&t=622s

He speaks in Spanish but you can get the subtitles in English. The videos are all free - all he asks is that you ‘like’ the videos.

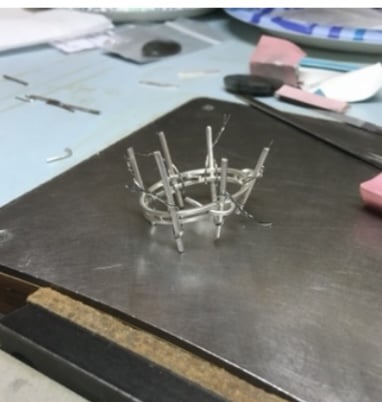

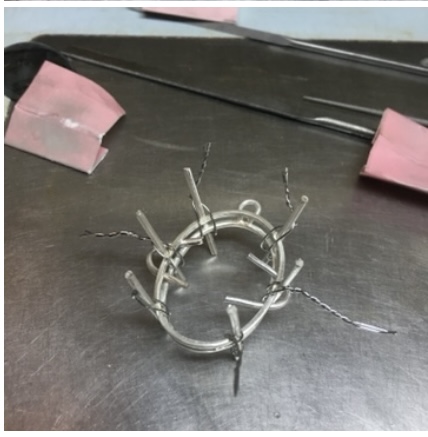

But that isn’t the type of filigree I wanted your feedback on - instead it’s the technique I was taught in Amsterdam by a Canadian guy called Jose. See photo for an example. You can see the little wire shapes that make up the ring - they’re the bits I want to hold in place.

I’ve now discovered there is something called soldering clay which does just what I need - ThermoFix available at https://www.uhrmacherwerkzeuge.com/epages/62662707.sf/de_DE/?ObjectPath=/Shops/62662707/Products/4211.

Thanks again to everyone

David

hi

ahhh i see!

it seems like one woul solder most on the flat? and then shape and solder closed?

perhaps solder in stages…perhaps 2-3 heats with hard…then 2-3 heats with medium, etc…with each heat, soldering multiple joints at same time…using yellow ochre or rhonda coryells nasking mud to protect previously soldered joints…?

some other options to think about:

use stainless steel binding wire…can strategically place dirty lengths of broken burs or wire between to keep wires away from joints…and use yellow ochre to protect previously soldered joints…

can use soft magnesium soldering blocks, and sewing pins or T-pins to pressure fit/ press together/ hold pieces steady/ tight/ together…

https://www.ottofrei.com/Magnesia-Soldering-Block

julie

Where do you live David? I’m in Orlando Florida. What you have in your picture is what I do mostly besides the Russian filigree. I could pass on many little tricks that will make that kind of work SO VERY EASY. I speak Danish. Danish and Dutch are close and I can figure out what is being said. I can usually figure out what is the meaning of the written Dutch as well. Not many who speak Danish in middle Florida.

Aggie

Hi Aggie - I live in Nantwich, a small town in Cheshire in North west England. I’d love to hear your little tricks and see some of your work. I’ve got a shop on Etsy 3rdStoneSilver (all one word is Etsy’s style) but due to an IT issue its way out of date - I need to add a load of new listings in the next few days. That’s great you speak Danish - I learned a little of that back in the 80s when I worked for a pharmaceutical company and had to attend Danish and Pan-Scandinavian conferences. I can well believe there’s not many others like you in the Alligator state though!!!

Thanks for your so-friendly response

All the best

David

Oh Julie - thank you - those magnesium blocks sound like they could be the long-term solution I need - I’d never heard of them before. And Yes - I solder the various links together on the flat and then just bend them round a ring mandrel and solder the final joints to form the ring. It’s that soldering on the flat that I wanted people’s feedback on. This forum is fabulous - you are all just so helpful and positive. Thanks again everyone

All the best

David

I use Flamehold heat resistant compound, by Rockmount Research & Alloys, for keeping small parts together for soldering. It works great and can be reconstituted with water!

Not the best photo example but it’s all I can find currently. The post catch made lining up the tab and slot difficult hence the use of the clay to keep the two pieces together while soldering.

Was fabricating a replacement earring.

hi pblack

wonderful share!

thank you!

hi dan,

is this the thermo fix you are mentioning?

https://www.ottofrei.com/Thermo-Fix-Soldering-Clay

julie

Hi all

thanks for the Flamehold heat resistant compound recommendation and yes - ThermoFix is the stuff I’ve ordered. I’m still going to try the other suggestions and will report back on them later

David

Wolf Clay is available in a smaller amount than some other products, and therefor less $. Here is a video: Soldering with Kate Wolf's Soldering Clay - YouTube

The Wolf Clay looks very similar to the Flamehold. Any idea if it is a similar product/slightly different mix due to licenses/patents similar to JetBalistic vs Thermolock?

I like the idea of being able to buy smaller quantities of the Wolf Clay. I got my original portion of Flamehold from New Approach when I was a student there 6 years ago.

hi pblack

i think jettballistic and thermoloc are holding materials that become pliable at much lower temperatures…and not suitable for holding pieces while soldering…

julie