You need to get some blue pumice wheels. The kind made with actual pumice, not SiC.

I generally set cabs with thick walls and use a hammer and a polished

setting punch. I hammer the walls of the bezel 80% of the way down to the

stone. Then like Gerry Lewy, I use a highly polished and very sharp graver

to make a nice little bright cut on the inside edge where the bezel will

touch the stone. I always use a little oil or spit on the graver to help it

slide along and reduce the chances of scratching the stone. Once I’ve done

that then I hammer the metal the rest of the way down. If I have to use a

pumice wheel or fine file to remove any bumps or flaws I then use the

thumbnail of my hand holding the piece to protect the stone .I place the

top edge of my thumb nail right along where the bezel meets the stone. I

consider my thumb nails as my best tools.

If there are any scuffs or slight scratches on a soft stone they are easy

to remove with Zam, Crystal polish or tin oxide or chrome oxide.

Have fun and make lots of jewelry.

-Jo Haemer

www.timothywgreen.com

Try # 180 grit, this density is quite harmless on softer stones.

Gerry! On my Teaching iPhone!

Rob!

As I mentioned on another posting I use ONLY

#180 grit. I find it so safe and easy to use. I have the Tapered and the Flat-face configuration!

It works easy, just like “butter on bread”!!..

Gerry! On my Teaching iPhone!

Thanks to everyone who has contributed to answering this post. About a year ago I decided to stop using thin roll over bezels and learn to make and use heavy walled bezels. It has been an interesting year. I have learned a lot, thanks in part to those of you who answered my earlier general questions and now, more recently, my more specific questions about soft stones. Since I am retired, I have also had the time to research the archives and then just experiment in my shop trying to apply that which I have learned from all of you and my research. In between, I have made a lot of jewelry. I will keep refining my stone setting process, try to learn how to make and use gravers, at least to bright cut and then refine my stone cutting process so that it is compatible with how I set them. Thanks again and enjoy the season…Rob

Rob

Thanks for your great posting. That’s just why we’re here on Ganoksin. Enjoy your “learning-curve”. Retirement is for the older folks, work and stay young!..

Gerry! On my Teaching iPhone!

Robert Meitner, what gauge bezel do you

use for thick wall bezels?

I use at least 1.75 <-> 2.00 mm’s but in gauge…?? Any help?

*Gerry Lewy *

Toronto.

- (905) 886-5961 *

It depends on the size of the stone and style of the piece, but 1 - 1.5 mm to start…Rob

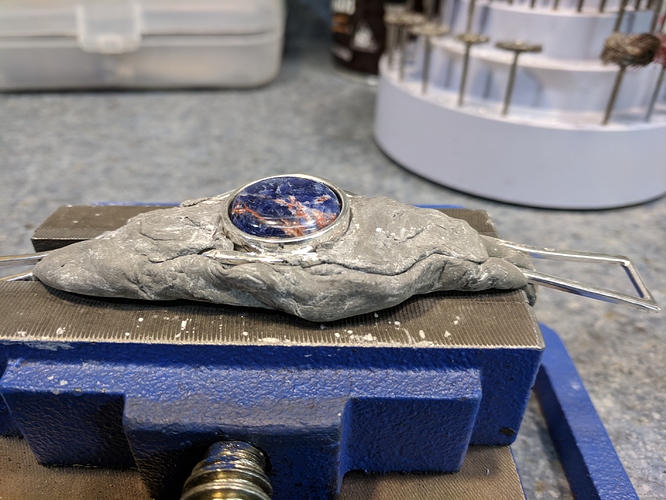

Following are pictures of my setup to set soft stones in heavy walled bezels. This bezel is 1.5 mm thick and the stone is Sodalite (I think). The punches are made from brass rod and the ends are polished. The gray material is Therma-Set plastic…Rob

Beautiful!

These are polishing wheels that do not damage stones as an alternative. Question is whether you can get them in US. I buy them from www.bijoumoderne.com in Holland. They do ship to US, but you have to inform at their customerservice wether it is worth your while. Often the shipping cost are high. Brandname is Eveflex.

They have flat round with straight edge, birdtongshape (ufo) and straight cilinder, don’t know what you call them in English.

0813876 EVEFLEX SCHIJFJE 22X3 MM GROEN/SF

08138761 EVEFLEX SCHIJFJE 22X1 MM GROEN/SF

08138763 EVEFLEX VOGELTONG 22X4 MM GROEN (birdtong shape works very good)

08138764 EVEFLEX CYL.10X12 MM M/STIFT GROEN

08138765 EVEFLEX CYL.14X12 MM M/STIFT GROEN

Eve wheels are available from US sources. They may be the same or similar to those that you have listed in your post. Thanks…Rob

While planning (to hammer down a thick walled bezel), how do you determine the extra smidgen of bezel height, in order to compensate for the height that gets hammered down? Is there a formula? It seems kind-of like planning the length to cut a rivet.

Others may, and maybe I should too, but I don’t worry about it. I worry more about it being high enough so that it stands a bit above the bracelet base once I am done. I do this by eye. I will measure how much is lost in height the next time and post the results. Good question, Thanks!..Rob

Hi Betty,

your reference to rivetng brings your question into the a well established engineering and tech formula for determining the correct rivet length. Thats also determined by the rivet size and the material to be riveted together., trying to transpose these parameters to a hammered over bezel setting really cant apply. My view from an engineering point of view is to try it out on a test piece say

with 1mm extra.

It will also depend on the curvature of the stone? being set. the more vertical it is the higher it will need to be.

common sense determines this. you dont want the stone to fall out? Nor hammer too hard and crack the stone.

If it was me id use a cone shaped tool to press in the bezel equally all at the same time.

But as you know im a press man! mechanise everything.

Ted.

ted.

Have you tried the fine or extra fine grade Craytex wheels or sticks? My forte has been lapidary and I haven’t done a lot of silversmithing. But back when I was doing a little stone setting I used the Craytex wheels to clean off tool marks from prongs and do not recall ever having any damage problems to softer stones from them.

Also someone mentioned ZAM which is Aluminum Oxide and Chrome Oxide mixed with a wax binder. Aluminum Oxide (also sold as Linde A, Raybrite, Sapphire Powder, and Alumina) is a good polish for both Turquoise and Lapis. And Chrome Oxide is a good polish for Lapis too.

As for those unsure on how to distinguish Lapis from Sodalite, just do a streak test on an unglazed ceramic tile. Lapis will streak blue, and Sodalite will streak white or light gray.

To find out if Lapis has been dyed just soak it for a little while in lacquer thinner. If the lacquer thinner starts turning blue then it is dyed.

Also watch out for imported commercial Lapis cabs that have been waxed instead of given a proper polish. I’ve also seen some imported Lapis cabs that have a clear plastic-like coating rather than being polished.

Larry Cashatt

Larry, Crafted abrasives work fine in metal, but the abrasive itself is either aluminum oxide or silicon carbide, both if which are harder than most stones. Very fine, polishing grits might not easily leave visible marks, but they could at least degrade a polish, especially on facet junctions. If one is careful not to hit the stone, then no problem. But that is why pumice abrasives are commonly used when rubber wheels are used to clean up prongs or bezel. Pumice can still leave a mark on some very soft stones, but some of those same stones often are going to have those same slight scuffs fixed just when you go to polish the piece. Also, a couple suggestions. Most socialite is at least somewhat translucent, while lapis generally is not. A penlight near a thinner edge, or Just looking at the surface with a loupe under strong light can usually pick that up. Plus, sidalite usually has patterns of internal fractures that lapis will not. Both of these examinations are quicker and easier than a streak test once one is familiar with the stones. And finally, rather than soaking a suspected dyed Lapis in acetone, use a little acetone on a cotton swab on the back or an edge. You’ll see the due come off on the swab long before a soak will color a mass of liquid, plus soaking the whole stone often will damage either the apparent (dyed) color, or the polish, or both, while you can avoid this with the swab in an inconspicuous spot. If its a customers, or dealers stone, that can be a consideration.Peter Rowe

I found a couple small bags of blue pumice wheels that I had forgotten about. A couple wheels had actually fused to each other and I had to cut them apart. They work well for cleaning up around bezels. I will add them to my flex shaft wheel kit. I especially appreciate the lapidary suggestions. My aborted Geology major (changed to Physical Geography) courses keep coming back to me as I read them and will definitely apply them to figuring out what kind of material I have. Is there a lapidary group that anyone can suggest that I participate in? I do belong to a Gem and Mineral Club, but can’t seem to get to the meetings. Happy Holidays to all…Rob