Hi Ganoksin

projet mjp 2500 and above are the best now for castable wax for jewelry

I think most SLS printers can print in wax resin.

The challenge may be that the most expensive printers use “casettes” or containers which communicate with printers to avoid them to use other than “official” resins.

I have an Elegoo and use Anycubic and Prusa resin, no problem. So it should be possible to use the Solidscape resin in these printers, unless they are designed to cure at other wavelenghts than them.

There are many brands of wax resins and also non wax resins that burn out fine.

The burnout of these castable resins is definitely tricky. Through a lot of trial and error we’ve managed to get very decent, consistent results. The Prusa printer is one I’ve yet to work with, but would love to take a crack at it (it has a slightly different mechanism for ‘peeling’ the print out of the vat with each layer).

As to your question about 3D printers that use material similar to the Solidscape: I’m all but certain that they have a patent for the piezo-electric jets that they use. So, while you can buy the wax from the guy who invented it (a guy named Kempton, who also invented the jets as well, but doesn’t have the patent for them…I could go on and on about the horrid history of Solidscape, but I won’t), you won’t be able to put them in anything that would utilize them, other than a Solidscape printer.

So, your choices become either drop the funds on a S390, or work towards getting reliable castings from a resin based printer (or, I suppose, go down the route of milling machines). We’ve got 4 resin printers now (just picked up the brand new Anycubic Photon Ultra dlp printer), and they are our bread and butter. It’s been almost 2 years since we put both our Solidcape MM2s in the basement, along with our Sanders Prototype RT2020 (which I still would like to get up and running, since it’s a little slice of 3D printer history).

Resins can be pretty easily swapped between LCD and DLP printers, but generally not SLS. Because of the use of the laser for curing, the SLS resins are designed to absorb a much higher wattage light. So, while you may be able to get away with putting a resin designed for LCD/DLP in an SLS printer, you most likely wouldn’t be able to go the other way, simply because the LCD screens aren’t typically powerful enough.

Thinking on it, you might be able to get an SLS resin to print on an LCD printer if you crank your exposure times through the roof.

I think I might try that out, as we have 2 LCD, 1 DLP, and 1 SLS printer on hand.

What resin and curing procedure have you hit on for the LCD’s?

Thanks AurumArcanum for setting me straight, and sadly I got the acronyms wrong… again.

You will get wax resins for most printers, but I have heard that some still use plain resins and their own burnout cycles for a variety of reasons.

I think though that if one have larger pieces, the resin printer’s ability to hollow out the prints will overcome the dangers of cracking due to thermal expansion, if done correctly that is.

So it definitely a tool that most likely will get even more important in the future.

Regards Per-Ove

I’m particularly fond of the resins sold by Power Resins. They make a variety of resins that are each tuned for a different purpose. We do a lot of stone-in-place casting, so their Wax resin is our current go-to. I’ve used most of what they sell, and they are all quite good. They don’t require any post-curing, so you just clean and dry them, and they’re ready to invest.

As far as specific cure times, that will vary a little for each printer. They have recommended cure times listed on their website for a large variety of printers; then it’s just a matter of fine tuning it to get the results you want.

I definitely want to explore the ability to hollow out prints. It’s a little harder with small jewelry, since the places where we tend to get the most breakdown are in the smallest areas where you can’t effectively print hollow (like fine filigree), but it would be really interesting to see how it effects the surface quality of shanks.

One thing to keep in mind when printing larger, hollow items though: you will generally need to have a drain hole somewhere, so you can get alcohol in there to clean out the inside. Uncured resin does not have the same thermal characteristics as cured, so you’ll end up with a lot more gas buildup within the print, potentially causing even worse thermal expansion.

Many thanks for your considered responses. We will investigate the various resins.

I currently have an Anycubic Chiron and Mono X. Can anyone recommend a resin for the Mono X that is available in Canada?

Thanks

Depends if you want a resin to make an RTV mold from or cast directly, but I believe this source in Ontario has both.

The source didn’t come through first time. It’s Resin Works in Ontario

PowerResins ships worldwide. I believe they are based in Turkey. You may have to pay some kind of tax though. I’m not too up to speed on what it costs to buy stuff in other countries.

Hello! I know it’s been quite a while since the last activity from this thread. I had some troubles with the resin casting for a while and looks like I don’t get the answer that I’m looking for from suppliers.

So I have basically 2 problems with my resin casting:

-

Stamp/Deboss/Logo: Anything related to design that stamped/indented into the surface sometimes lead to investment cracking.

-

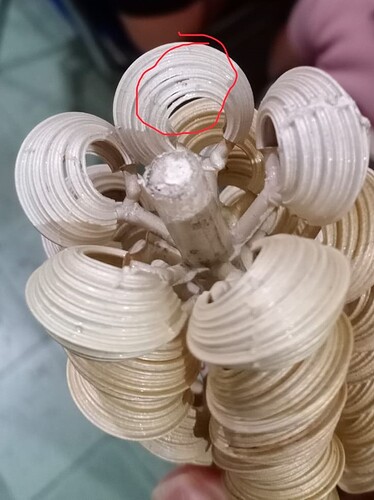

Finning at the top side of the tree, the worst case is metal not filled for piece at the highest part of the tree (and only at the highest one).

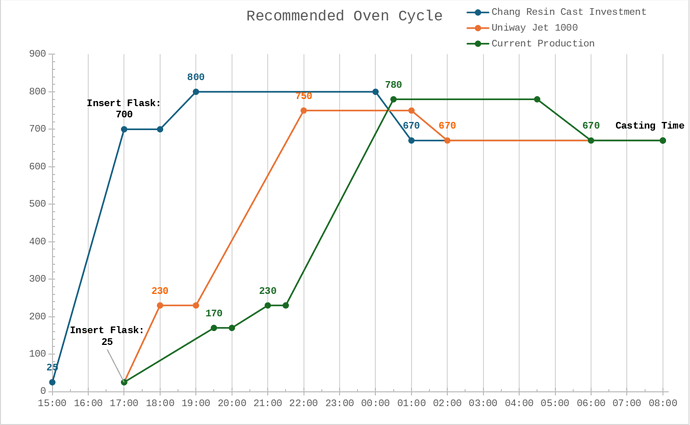

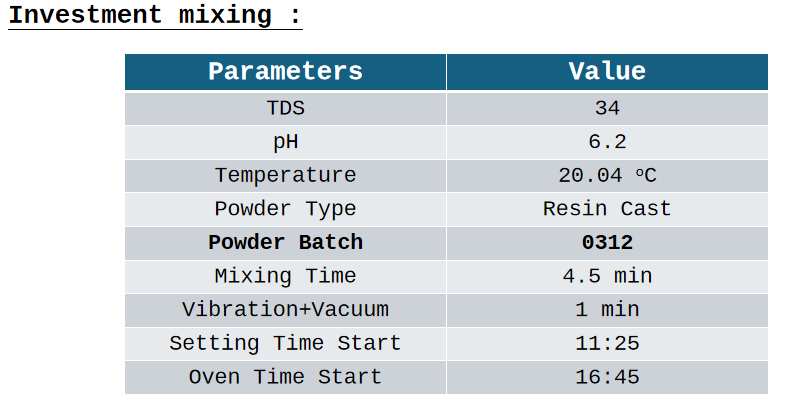

For stamp problem we’ve tried many ways to avoid it. From changing investment powder to manipulating burnout cycle. We’ve tried Resincast from Chang and Prestige Optima from Certus, both shows similar defect. Interestingly when we tried wax pattern with the same powder and burnout cycle we have no issue regarding the stamp. I believe this happened due to resin rapid expansion that we haven’t found solution yet.

Let me know what are you’re thought on my problems. Thank you for your time!

This is a link to a previous thread you might get something out of it

Good luck with solving the issue your having